The EEIP members have an excellent and extensive infrastructure to execute their research activities for their projects. The facilities listed below are among some of the research facilities used by our members.

No less than fifteen percent of the energy used by industry is needed for dewatering and drying processses This occurs mainly during the production of paper, chemicals and food. Innovations in this field are generally aimed at improving product quality, while there is also much to be gained from energy savings. TNO is taking up this challenge with the Mollier facility.

With financial support from the Ministry of Economic Affairs and Climate Policy, TNO will build an advanced infrastructure with equipment to experiment with different types of dewatering and drying technologies in the coming period. Discussions are ongoing with industrial end-users and equipment manufacturers about the exact details of the research programmes that will start this year

Read More

National Laboratories for an Energy Efficient Industry for improved utilization of available industrial surplus heat and a reformation of the efficiency in various industry processes.

Read More

Accelerate Sustainable Industrial Heat Management

Achieving the climate objectives in industry requires more research and development into industrial heat technologies. More than 80% of industrial energy consumption is related to the use of heat, which could prove beneficial on the way to a sustainable energy economy. The Carnot lab, which recently expanded its facilities, is taking up this challenge. This heat lab in Petten offers companies the unique opportunity to further develop industrial heat technology on a small and large scale together with TNO.

Read MoreAs the Combustion and Gasification Laboratory developed, there was an increasing need to properly prepare the fuel for testing, e.g. drying, grinding or separating the dust into its various fractions. In the case of low-power stations up to 10 kW and short-term tests, typical laboratory equipment such as dryers, grinders or shakers were sufficient. However, for long-term tests, i.e. tests on a 0.5 MW stand and a 150 kW gas generator, fuel preparation in this way would be impossible.

The Fuel Preparation Laboratory was established in 2008 and comprises two locations in Warsaw. The total area of the laboratory is approximately 650 m2.

The Research Fuel Preparation Laboratory comprises three large research installations:

- the coal dust preparation installation,

- the dust fractionation installation,

- installations for the preparation of fuels from biomass and biodegradable waste in the form of dust, pellets and briquettes,

- and smaller more typical installations or the equipment itself (mills, shakers, crushers).

The first and second of the above-mentioned installations offer the possibility of safely preparing hard coal and lignite dust of an appropriate grain size (R90<2% and R200<10%) and moisture content (hard coal 1.5-5%; lignite 10-15%) for testing combustion processes in pulverised fuel burners and gas-generators. For fuel preparation volumes below 500kg, the above parameters can be significantly improved by carrying out ‘manual’ drying and screening of undesirable fractions.

The installation for the preparation of biomass and waste fuels offers the possibility to prepare dust and pellets from biodegradable fuels (vegetable waste) as well as briquettes with a diameter of 40 mm from any suitably prepared waste for energy production.

Supervisors of the installation and equipment:

- Grzegorz Nehring, M.Sc., e-mail: grzegorz.nehring@ien.com.pl

- technician Krzysztof Groszewski, e-mail: krzysztof.groszewski@ien.com.pl

Analytical control of the gasification process

Work carried out:

- gas quality assessment:

- gas composition,

- dust,

- tars: quantitative and qualitative determinations according to PKN-CEN/TS 15439,

- H2S, HCl,

- water vapour by the Fisher method,

- other by-products,

- analysis of the suitability of biofuels for energy production,

- studies of pyrolysis and gasification process parameters for various types of biomass.

Measurement offer

- comprehensive services at customer installations including gas composition studies and sampling, process balancing,

- analysis of PAH compounds in solutions, e.g. tar samples,

- leaching and chromatographic analysis of tars samples taken by SPA method,

- certified balance measurements of gasification installations,

- analysis of the suitability of biofuels for energy production,

- studies of pyrolysis and gasification process parameters for various types of biomass using the macro-TGA technique.

Analytical offer

Portable measuring equipment

- gas conditioning systems for analysis

- hot and cold sampling

- CO, CO2, CH4, H2 and O2 measurements (Siemens Ultramat 23 and Calomat 6),

- NH3, HCl, and others to be determined (Gasmet DX-4000 FTIR),

- C2-C10, BTX, Ar, N2 (Varian CP4900 micro-GC).

Stationary measuring equipment

- thermogravimetric analyser TGA701, by LECO,

- ash fusion analyser AF700, by LECO,

- oxygen determination attachment, by LECO,

- macro-TGA test stand.

The stand is used to test the pyrolysis and gasification process of biomass and biodegradable waste.

The apparatus allows for:

- conduct the process by slow and fast pyrolysis methods,

- macro-TGA pyrolysis and gasification processes.

Fuel Analysis Laboratory

The Combustion and Gasification Laboratory is the oldest existing laboratory in the Thermal Processes Department. From the beginning of its existence, the main goal of the laboratory was to develop new technologies and techniques for burning hard coal and brown coal. Over time, the laboratory's activities were expanded to new directions, such as gasification of solid fuels, combustion of low-calorie gases, combustion and co-combustion of alternative fuels, development of fuel cell technology, etc. The laboratory has an area of approximately 400 m2 and primarily houses research stations and specialist measurement and research equipment. The scale of the stations allows both the examination of partial processes occurring in individual grains and the assessment of combustion stability using a given dust burner on a semi-technical scale. The laboratory is also prepared to conduct research on exhaust gas purification processes from harmful chemical compounds using, for example, the SCR or SNCR method. It is also worth emphasizing the possibilities of testing the combustion of solid fuels in oxygen conditions at research stations with the possibility of using oxygen, carbon dioxide, steam, nitrogen oxides and sulfur dioxides together with the appropriate grading of the oxidizer and its administration at the right temperature (up to 1400 degrees Celsius).

Specialized research equipment ensures proper diagnostics of the tested processes. The Thermal Processes Department is able to measure almost all gaseous compounds in exhaust gases and gases that are interesting from the point of view of combustion and gasification. In turn, the Optical Flame Diagnostics System together with equipment enabling the measurement of half-velocity (PIV), particle temperature (two-color pyrometer), radiative heat flux (radiometers) and slagging and deposition processes is able to provide not only interesting data on the process itself but also support mathematical modeling in order to verify the models themselves and improve the results of numerical simulations of real power boilers and accompanying devices.

The Laboratory consists of the following research stations:

A station for testing the explosiveness of gas, dust and hybrid mixtures in ambient conditions and elevated temperatures

The station enables:

- determining the explosiveness characteristics of the above mixtures also in conditions of elevated initial temperature up to approx. 350oC,

- determining the explosiveness characteristics of pyzolic gases from biomass,

- determining the maximum explosion pressure,

- determining the maximum pressure rise rate,

- determining the lower explosive limit,

- determining the limiting oxygen concentration.

Station supervisor: Dr. Eng. Paweł Bocian, e-mail: pawel.bocian@ien.com.pl

Single grain combustion test stand

The stand enables:

- conducting basic tests of solid fuel ignition by performing an experiment of rapid combustion of a solid fuel particle in given temperature conditions and with a given composition of the oxidizing atmosphere,

- recording the experiment using a fast camera and a computer data archiving system,

- providing information for the verification of numerical models

Station supervisor: mgr inż. Ewa Marek, e-mail: ewa.marek@ien.com.pl

Stands for testing the kinetics of degassing of volatile parts (PEST) and oxidation of coke residue (CORD)

The research stands enable:

- testing the degassing of volatile parts, i.e. determining the rate of release of gaseous compounds and their composition in inert atmosphere conditions,

- testing the combustion of coke residue, i.e. determining the rate of combustion of coke residue (reactivity) in conventional combustion conditions and in an oxygen-enriched

- atmosphere,

- testing the kinetics of NOx, SO2 release during fuel combustion in various combustion systems,

- testing NOx reduction techniques using primary and secondary methods. {gallery}structure/heating-pipe/position{/gallery}

The 1.5 m long reactor (PEST) is equipped with a movable, vertical receiving probe 2 m long, which allows for taking a sample at any stage of degassing, while the 6 m long reactor (CORD) is equipped with a horizontal probe, which, using nozzles placed along the entire length of the reactor, allows for taking ash samples throughout the entire range of the fuel's residence time in the chamber. The collection of gaseous reaction products is carried out using a gas sampling and conditioning system, fed to the exhaust gas analyzer. Isokinetic gas sampling, the so-called hot exhaust gas path and the FTIR analyzer allow for the identification of gas components at various stages of the combustion process, such as: CO, CO2, O2, SO2, NO, N2O, NO2, HCl, HF, NH3, HCN, HNCO, H2O, CH3NH2, CH4.

Position supervisor: Dr. Eng. Jarosław Hercog, e-mail: jaroslaw.hercog@ien.com.pl

Stand for testing the ignition of solid fuels

The research station adapted for testing the combustion of solid fuels in the form of dust is used for:

- determining ignition and combustion characteristics,

- testing the effect of the chamber temperature and the flow and composition of the primary factor

- otive and secondary on the stability of dust cloud ignition,

- studying the effect of the type and amount of various additives to the reference fuel (e.g. a mixture of biomass and coal) on the nature of combustion.

- providing real information for numerical modelling of combustion processes and burner design.

The stand is equipped with a system of heaters and electronic flow regulators. Connected to a computer data archiving system. The course of the experiment is recorded using a digital camera enabling tracking of the ignition and combustion history along the entire length of the downpipe.

Station supervisor: Dr. Eng. Paweł Bocian, e-mail: pawel.bocian@ien.com.pl

Station for testing the intensity of coal slagging

The stand is used for:

- comparative studies of the tendency to slagging of coals and other fuels in conditions similar to those prevailing in boiler combustion chambers,

- determining the relationship between slagging intensity and exhaust gas temperature; such dependencies well characterize the changes that occur in coal ash during combustion,

- reflecting such properties of ash as its viscosity, adhesive properties and other parameters that are not examined during chemical analyses of ash.

Position supervisor: Eng. Jerzy Szymczak, e-mail: jerzy.szymczak@ien.com.pl

Stand for burning solid and gaseous fuels with a power of 0.5 MW

The stand enables:

- testing new burner designs in terms of their stability and limit values of operating parameters,

- testing the behavior of various fuels (including coal dust, biomass, waste fuels) during combustion and co-combustion on a semi-technical scale,

- testing the fuel combustion process both in air and in other atmospheres, O2, CO2, N2, water vapor, nitrogen oxide, sulfur dioxide,

- testing exhaust gas purification processes (so-called post combustion) using SCR or SNCR methods and others,

- testing slagging and deposition processes and corrosion,

- testing the combustion processes of low-calorie gases (syngases). The test stand is equipped with a control and measurement system that enables visualization and recording of many

- parameters of the stand's operation (flows of factors, temperatures and pressures in various parts of the installation, composition of exhaust gases in the combustion chamber, etc.).

The fully automated stand is additionally supported by the recording from a high-speed camera, allowing for an in-depth analysis of the processes occurring in the combustion chamber.

The stand is being expanded to adapt to measurements using non-contact methods: velocity fields (PIV), distribution of gas components NO, OH, CH, CN, CHC2, C2 (LIF), dust concentration in the chamber (LII) and reaction zones (ES). A new combustion chamber module with larger windows is being added.

New combustion chamber module with large windows for lasers and cameras of the PIV, LIF, LII and ES systems.

Specialized Research Equipment

- Optical Flame Diagnostics System

Laser flame testing techniques known for many years and used, for example, in the automotive industry, such as Laser Induced Fluorescence (PLIF), Emission Spectroscopy (ES) or Laser Induced Incandescence (LII), have been used in the Combustion and Gasification Laboratory in a unique way, because they are used to test the flame during combustion of solid, liquid and gaseous fuels on a scale of 0.5 MWt.

Using the above techniques, it is possible to determine the concentrations of NO, OH, CH, CN, C2, particle concentration, reaction zone and the shape, position and stability of the flame.

- PIV

The Optical Flame Diagnostics System has been supplemented with a non-contact system for measuring velocity fields in the combustion chamber, which enables testing of aerodynamics in the burner zone. The equipment allows determining the velocity profile in three dimensions.

This was achieved by constructing an additional station module equipped with a special system of speculums made of synthetic quartz with high UV radiation transmittance and a system for traversing the laser light knife and cameras.

- Two-Color Pyrometer

The device is used for non-contact measurement of the temperature of surfaces with unknown emissivity. The essence of its operation is the detection of infrared radiation emitted by the body. The range of wavelength measurement has been specially selected for the needs of the experiments carried out and ranges from approx. 1 µm to approx. 1.65 µm.

Basic technical data:

- min. measurement temp. ~500oC,

- max. measurement temp. ~3000oC,

- max. measurement frequency 500 kHz,

- max. measurement error <5%

- FTIR analyzers

The measurement of the concentration of a wide range of exhaust gas components is carried out using an analyzer operating on the basis of the Fourier transform principle in infrared.

Main features of the Gasmet DX-4000 FTIR analyzer:

- measurement in the "hot path" system,

- simultaneous measurement of up to 50 components

- analysis of, among others, CO, CO2, O2, SO2, NO, N2O, NO2, HCl, HF, NH3, HCN, HNCO, H2O, CH3NH2, CH4

- no calibration required (except for H2O once a year)

- Position supervisor: mgr inż. Krzysztof Jagiełło, e-mail: krzysztof.jagiello@ien.com.pl

150 kW Gasification Reactor

The research station, which includes a 150 kW gasification reactor with a fixed bed, is designed for continuous operation. The installation enables:

- testing the effect of the gasification agent (air, steam, oxygen, carbon dioxide) and its temperature (up to 800 oC) on the gasification process and the quality of the process gas,

- testing various fuels and determining their suitability for the gasification process,

- measuring the composition of the synthesis gas.

The gas from the gasification process becomes a fuel in the experiments conducted at a later stage using a low-calorie gas burner installed at the station for burning solid and gaseous fuels with a capacity of 0.5 MWt.

Station supervisor: mgr inż. Karol Białobłocki e-mail: karol.bialoblocki@ien.com.pl

30 kW gasification reactor

A laboratory installation based on a 30 kW co-current gasification reactor connected to a low-temperature gas cleaning line. The station is used to test energy production systems with gas application:

- in an internal combustion engine;

- in a fuel cell.

Station supervisor: mgr inż. Karol Białobłocki, e-mail: karol.bialoblocki@ien.com.pl

KJ 20 kW mini-gasifier station

A 20 kW gasification station built according to a patent for a gasification reactor enabling the production of gas of high purity and calorific value. The design of this reactor is an innovative technical solution. Current research work carried out using this design aims to:

- verify the functionality and optimize the reactor operating parameters (start-up, supply of gasifying agents)

- in the next stage, the KJ 20 kW prototype is to be used to optimize the process itself and the method of supplying process media, as well as the design of the reactor on a larger scale.

A laboratory for applied research in the field of social transformation and technological transition towards carbon neutrality, established within the Department of Industrial Economics and Management, Faculty of Economics and Business Administration, Sofia University‚ St. Kliment Ohridski.

The Net-Zero Lab @FEBA is a purpose-driven research unit within the Faculty of Economics and Business Administration of Sofia University.The lab activities are organized around three core areas:

- Techno-economic assessments of technological solutions in the energy and industry sectors necessary to meet the Net-Zero target

- Decision-support tools, such as energy system simulation and optimization software (Plexos), regional technology roadmaps for the sustainable transformation and life cycle carbon assessments.

- Applied research for societal transformation:

- 1). Assessing human resource needs for a sustainable future

- 2). Fostering social partnerships

- 3). Empowering individuals and communities to drive meaningful change.

Contact person:

Mariya Trifonova, Deputy Director, (mgtrifonova@feb.uni-sofia.bg)

Maya Todorova, Project Coordinator, (maya@feb.uni-sofia.bg)

In the context of Europe’s push toward industrial decarbonization—where industry accounts for approximately 25% of total energy consumption—high-temperature heat pumps offer a promising pathway to electrify thermal processes traditionally reliant on fossil fuels. A flexible and compact test rig based on the Brayton cycle has been developed to support this transition. Operating across multiple configurations (open/closed, with or without regeneration), the system is built with off-the-shelf components and advanced thermal modeling. It is capable of delivering up to 10 kW of heat at temperatures up to 135°C, and is designed as a platform for component testing, performance optimization, and validation of feasibility of small-scale high-temperature heat pump models.

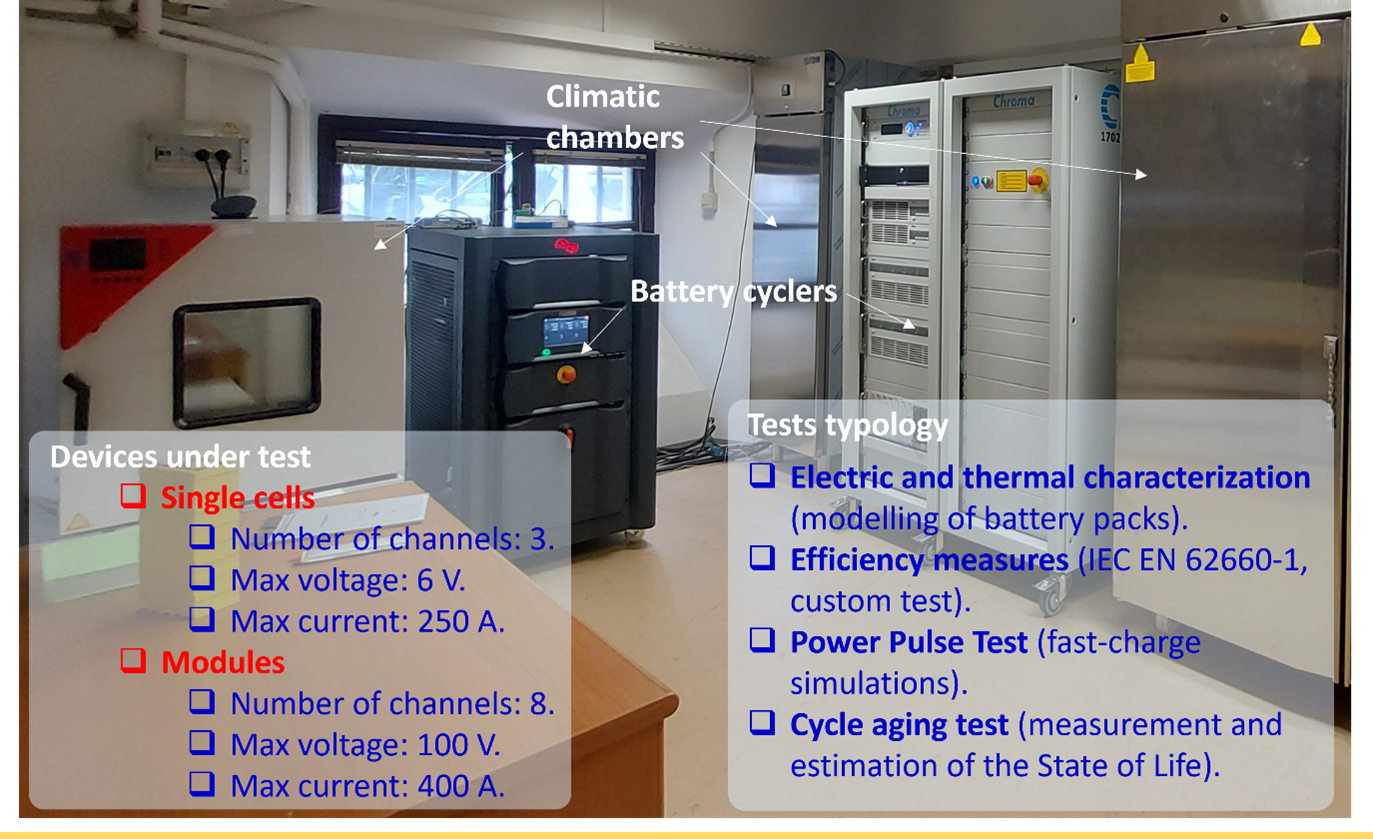

Supporting the growing demand for electric mobility and renewable energy integration, the REESS (Rechargeable Electrical Energy Storage Systems) laboratory provides advanced infrastructure for battery testing and characterization. The facility is equipped to perform a wide range of tests—including electrical and thermal modeling, efficiency measurements, power pulse simulations, and cycle aging analysis—on both single cells and battery modules. High-performance battery cyclers (up to 100 V, 400 A) and programmable climatic chambers (from –40°C to +180°C) enable precise control of testing conditions.